What Is Metal Spinning? An Overview of the Process & Benefits

Metal spinning is a complex metalworking service which is used to manufacture axially symmetric parts from round metal discs, tubes, or cylindrical blanks. In some industrial applications, metal spinning solutions are essentially utilized as a quicker, more cost-efficient alternative to metal stamping.

Sometimes referred to as metal turning or spin forming, metal spinning services can be performed both manually and via CNC lathe. In either case, when you partner with experienced precision machine professionals at J&E Companies, spinning is a reliable and efficient method for producing complex custom metal components and prototypes.

HOW DOES METAL SPINNING OR SPIN FORMING WORK?

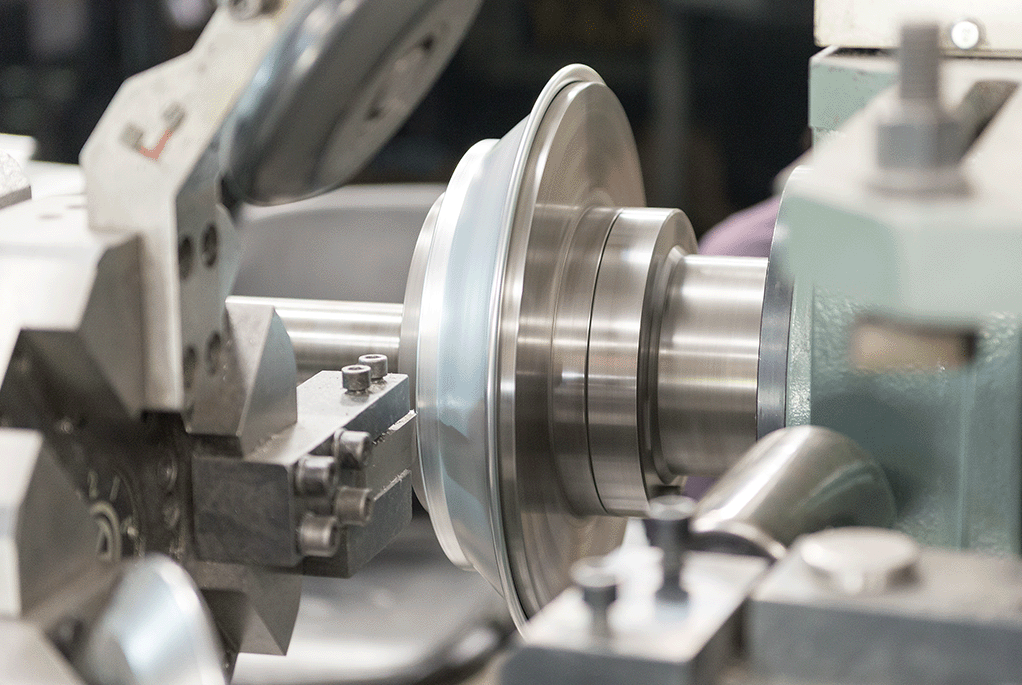

Metal spinning is a relatively simple process when compared to other precision metalworking services used throughout the modern machining industry. Utilizing a manual or CNC turning machine, a round or cylindrical chuck is fitted to the end of the lathe. The metal workpiece to be formed is then fitted against the chuck tool. Held firmly with a pressure pad, the workpiece is spun to the appropriate speed – in some cases approaching 2,000 rpm.

As the workpiece spins, our machinists carefully apply force using a range of specialized tools and rollers. In the case of CNC metal spinning, the tools are robotically controlled via custom CNC programming to provide higher precision, consistency, and closer tolerances. We can even form complex components and prototypes through multi-axis forming, manipulating the workpiece with multiple chucks simultaneously to achieve unique part features and geometries.

THE BENEFITS OF METAL SPINNING IN PROTOTYPE AND PRODUCTION APPLICATIONS

Efficient and Cost-Effective

Metal spinning services are often a much more cost-effective alternative to metal stamping and custom casting operations.

Rapid Turnaround Times

In addition to being more cost-efficient, spin forming is often the quickest manufacturing option for your custom components. Both setup and production times can be much speedier than conventional stamping options – especially for complex components which would require custom tool and die solutions.

Suitable for Prototype and Production – Both Low and High Volume

The speed of the process makes metal spinning ideal for many rapid prototyping applications. However, spin forming is a highly versatile process that is also perfect for full-scale production. Whether your project is for low-volume prototypes or a large-volume production run, J&E’s precision metal spinning capabilities may be the ideal solution.

THE ADVANTAGES OF J&E’S CNC AND MANUAL METAL SPINNING SERVICES

J&E offers a complete range of contract manufacturing services to accommodate your project, including custom metal spinning solutions. Our versatile machining shops in multiple locations utilize both automated CNC processes as well as manual spin forming. This flexibility combined with over half a century of manufacturing experience enables us to fulfill both small or large production orders quickly, accurately, and on time.

Get in touch to discover all of the advantages of J&E’s superior metal spinning services.